Application

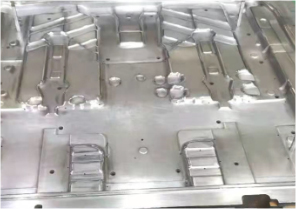

The products are mainly applied in automotive parts of BIW, chassis, seat, battery enclosure and roof systems

More>>

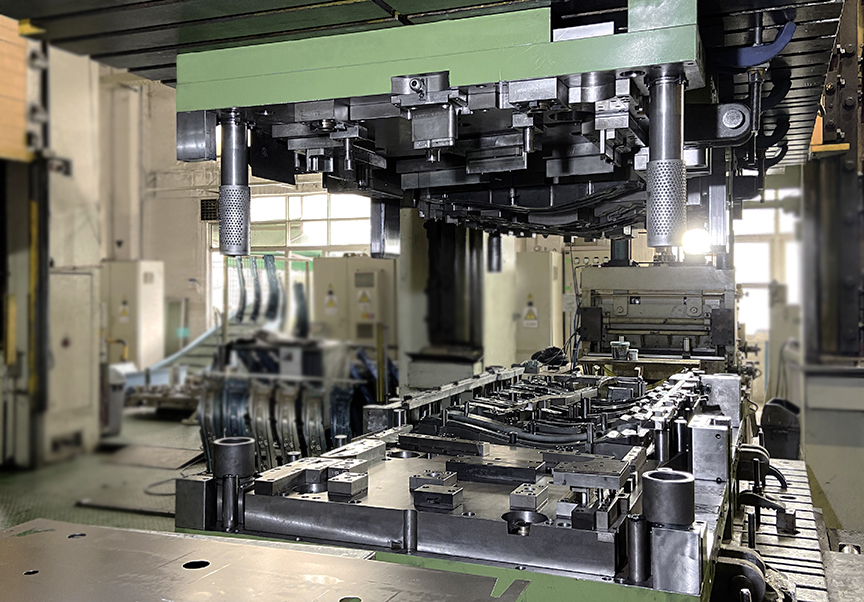

Cold-Forming Tool Division

Cold Forming Tool, A Division of Vision Tool, Focuses on Designing and Manufacturing Cold Forming Tools to Produce Automotive Metal Parts Including Big Progressive Die, Transfer Die, Tandem Die, and Compound Die. It Currently Employs Over 200 Engineers and more than 220 Toolmakers. Equipped with 129 sets of CNCs and 17 sets of presses up to 2000T, We Provide Customers an Integrated Solution with High-quality Tools and Services.

Application

The products are mainly applied in automotive parts of BIW, chassis, seat, battery enclosure and roof systems

More>>

Engineering –There are 204 process and design engineers, they all have Engineering Degree and worked on floor for years before moving to office. Assembly - 100 die-makers for progressive dies and 124 die-makers for transfer dies work for two shifts with an average of 10-15 years tooling experience.

.png)

01

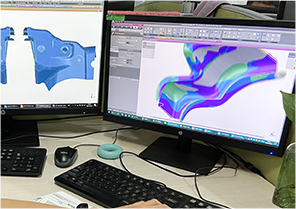

Build experimental lab & material parameter database

02

Complete CAE modeling simulation analysis system

03

Use Tianhe-2 Supercomputer to do CAE fine analysis

04

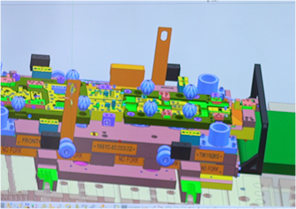

Realize intelligent and modular structure design, automatic drawing and programming

05

Cooperate with universities to conduct research on new materials and technologies

01

Customer Demand Leading-in

Hold a project kick-off meeting to fully introduce customer demands and standards.

02

Design Period

Each design completion follows up with internal review before submission.

03

Incoming Material Inspection

Both own Lab and the independent 3rd party can test the customer-supplied tryout material to verify the spec; TOMS detectors scan is used for casting inspection.

04

Die Assembly Inspection and Internal Buyoff

Pre-assemble all parts to fit in first, then complete full die assembly to ensure the correct clearance, and solve the problems in advance to ensure smooth tryouts.

05

Customer Buyoff and Homeline Support

Customer Buyoff can be completed both virtually and in person on site by the local engineers; Homeline Support can be commissioned by our local die-makers and/or by the ones from China who built those tools.